Design Practice

Harrison Park

Archives

Design for print- creative suite session 3

Indesign

Have discussion with printer before producing the final document, this will help him but also help us, discuss file format, spot colours, finishes, bleeds etc... To print on blurb, there is a plug in called blurb book creator that'll aid in setting up the document to print as it has to be very precise.

Slug area is used for printers marks and crop marks, things that aren't involved or visible in the final design. Can also put fold marks in the slug area, all aids in the printing process and finishing.

Primary text frame automatically adds a text frame to each page, very useful when creating text heavy documents, allows us to just copy and paste straight into the text box.

Applying colour

The way indesign applies colour is the same way illustrator applies colour, to shapes and frames. Swatch menu is different to the swatch menu on illustrator because it doesn't give us a range of default swatches, it's a much more practical swatch palette. The swatches are also automatically global unlike illustrator or photoshop, which means if we edit the colour anything that is that colour automatically changes.

Tint swatches are created when selecting a colour and selecting the new tint swatch menu.

When hovering over each little bit of detail in the photograph it actually tells you the percentage of each individual colour.

Red square shows the print limit, similar to gamut warning it warns when there is too much ink that will be applied, warning depending on what stock you're using. If using thin stock it is more relevant than if you were using thick 350gsm paper.

Have discussion with printer before producing the final document, this will help him but also help us, discuss file format, spot colours, finishes, bleeds etc... To print on blurb, there is a plug in called blurb book creator that'll aid in setting up the document to print as it has to be very precise.

Slug area is used for printers marks and crop marks, things that aren't involved or visible in the final design. Can also put fold marks in the slug area, all aids in the printing process and finishing.

Primary text frame automatically adds a text frame to each page, very useful when creating text heavy documents, allows us to just copy and paste straight into the text box.

Applying colour

The way indesign applies colour is the same way illustrator applies colour, to shapes and frames. Swatch menu is different to the swatch menu on illustrator because it doesn't give us a range of default swatches, it's a much more practical swatch palette. The swatches are also automatically global unlike illustrator or photoshop, which means if we edit the colour anything that is that colour automatically changes.

Spot colour swatches- Similar look but completely different print process.

When placing a duotone image to indesign the spot colours used in photoshop are automatically added the swatch palette on indesign. When working in photoshop there are several factors to bare in mind when preparing an image to be placed in Indesign; 300dpi, actual size, CMYK or spot, TIFF/PSD. In illustrator we don't have to worry about the dpi or actual size, we still need to bare in mind CMYK and saving AI. Indesign also allows us to copy and paste our illustrator artwork because the both work using vectors.

Separations

Indesign using the colour channels from photoshop to show how each individual colour is represented, they also remind us of individual screen positive when printing photographs, they're used for creating each individual plate used in commercial printing.

In order to make sure nothing goes wrong in the printing process it's best to delete all unused swatches just so that they aren't used in turn costing a client a lot of money.

Halftone, the smaller the dot the lighter the tint. For high quality print you'd be looking at 150 lines per inch, but a billboard is around 50, screen printing 40-65. The separations process is only available on certain printers, only the mac suite printers work well in uni because they're laser printer.

Attributes, overprint shows the outcome if the two colours were printed on top of each other

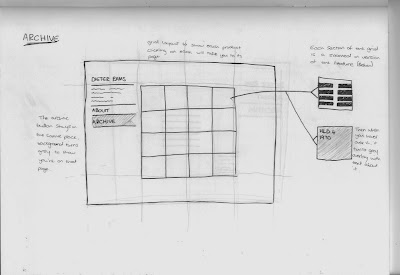

Design for web- final concept

At the beginning of this brief I struggled quite a lot deciding on a concept based upon my summer research and completed a couple of tasks to try and cement what it was that I was going to do, even going back and looking at why I chose to research Dieter Rams in the first place didn't help too much, it gave me a bit of an idea but I had to try and figure out how to try and convert that passion into a website. Firstly I revisited why I chose Dieter Rams;

Why Dieter Rams?

For my summer research I chose Dieter Rams to focus my research on because of the simplicity of his product design for Braun, they're extremely basic and minimal which aids in their timeless aesthetics, they wouldn't look out of place in a modern home nowadays. Each product features its own little iconic detail such as the snow whites coffin speaker holes or the air cooling holes in the hairdryers. Each product has a slightly different feature be it scale or shape but they mainly featured circular hole or strips, both vertical and horizontal, they were very simplistic in form and became the main feature of the product but remained unobtrusive to the purpose and functionality of the purpose.

From looking back at this I got some form of idea what be involved in the website, it wouldn't be a biography based website because there's plenty of those about already so that idea is pretty pointless. Then I thought of how I could incorporate these features I talk about and describe, this means the website would be aimed at people who are already knowledgable about Dieter Rams and have a passion for his designs. But then I thought to myself that why would these people want to visit a website that only showed features of a product...

Then it hit me as I was browsing through websites that had won awards, there was this one website that simply illustrated windows of New York, there is no actual purpose to it but it is for people who love design illustration. So why can't I create something similar for the people who love the design of Dieter Rams, the simplicity and features. There are plenty of prints out there focusing on the features but not websites from what I've found, there are apps that use the design of the Braun products as an interface for radios and music players but they only focus on one feature. What if I create a website that illustrates the features of a wide Braun product range?

Concept

From this I've come up with the concept of creating a website that is a aimed at the people who know about Dieter Rams and the braun products and aren't looking for any particular information about them, but are more interested in the design features, these people will have a passion for design and illustration, appreciating the simple concept of the website. The websites main focus isn't to educate or inform the viewer, it's mainly a novelty, a source of entertainment that provides small pockets of information about the product that particular feature came from. On the back of this it's up to the viewer if they go away and research more into this product because there's plenty of websites that all carry the same information that wikipedia does.

Concept

From this I've come up with the concept of creating a website that is a aimed at the people who know about Dieter Rams and the braun products and aren't looking for any particular information about them, but are more interested in the design features, these people will have a passion for design and illustration, appreciating the simple concept of the website. The websites main focus isn't to educate or inform the viewer, it's mainly a novelty, a source of entertainment that provides small pockets of information about the product that particular feature came from. On the back of this it's up to the viewer if they go away and research more into this product because there's plenty of websites that all carry the same information that wikipedia does.

Design for print- Content map

Today I've been focusing on the content of my info pack so I can make a start on researching and collating all the information I want to feature. To be honest I didn't really know where to start or what to include so I wrote a list of everything I could possibly think of along with other bit out of books and on the web. I then narrowed it down to what I thought was more specific to the concept of my info pack. Below is the post it note map I made of the contents, it isn't a definitive list though. I will probably add and subtract as I'm research, it's more of a guide as to where to begin researching and giving me structure during this process.

Because I'm focusing for print on paper certain categories are limited to what they're going to contain such as format and stock. This will aid my research process because it's focused down and not a vast broad range of stocks, which could be a never ending list because you can now print onto most things.

In case you can't read the text on the photo;

Production

Binding

Print features

Overprint

Format

Paper size

Paper uses

Process

Screen print

Scratch overlay

Thermo chromatic

Risograph

Lasercut

Stock

Weight

Texture

Choosing the correct stock

Notable paper sources

Paper types

Finishes

Foil blocking

Folding

De/Emboss

Duplex

Die cutting

Perforation

Colour

CMYK

Spot colours

Pantone

Inks

Design for print- formats and finishes

This morning we had a brief session with Phil looking at print formats and finishes;

Coated and uncoated paper stocks are easily distinguished by their appearance. A coated paper has a shimmer to its surfaces and will feel smooth and waxy to the touch, whereas uncoated papers appear matt and will feel rougher or grainier to the touch.

Coated papers are like a pane of glass whereas the uncoated papers are similar to a sponge. Printed coated papers will appear bright and colourful almost as though the inks were sitting on the surface whereas printed uncoated papers will appear duller and less vibrant where the inks have soaked into the paper's fibres.

Die cutting is a manufacturing process used to generate large numbers of the same shape from a material such as wood, plastic, metal or fabric. If we were to put it simply it is a way of making a hole in paper in a desired shape using the same presses that we use for letterpress printing.

Embossing is to raise an image up above the surface of the paper whereas

debossing pushes the image down into the surface of the paper. Either process can have colour or can be blind i.e. without colour. Both embossing and debossing are

produced on letterpress equipment and require film and metal dies to be made.

The litho-laminating process is a means of creating corrugated board that has a high quality, litho printed surface.

The litho-laminating process can be sub-divided into three main types - inline, offline, and sheet to sheet.

Duplex printing is a feature of computer printers and multifunction printers (MFPs) that allows the automatic printing of a sheet of paper on both sides.

Print devices without this capability can only print on a single side of paper,

sometimes called single sided printing.

Foil stamping, typically a commercial print process, is the application of pigment or metallic foil, often gold or silver. But can also be various patterns or what is known as pastel foil which is a flat opaque colour or white special film-backed material, to paper where a heated die is stamped onto the foil. Making it adhere to the surface leaving the design of the die on the paper.

With a focus on Stock, Substrate and ‘special’ Print Finishes find as many

variants as possible for each of the

following areas of Design:

> Branding and Identity

> Packaging and Promotion

> Publishing & Editorial

> Information & Wayfinding

You should consider production values, scale and functionality in relation to appropriate contexts and target audiences and evaluate their impact on the design decisions that have been made. Wherever possible you should aim to collect physical/actual examples of print as this will help you to evaluate the important tactile, formal and functional elements of your source material.

Design for print- concept

The concept is to create multiple print publication that are released similar to magazines in volume, each volume will focus on an area of print such as; colour or stock. They'll work individually but also together as a large set meaning they require to be bound somehow individually as well being able to be bound al together. The book will be the bog standard print resource on one side but on the other it'll be a dictionary of the words outside of design. This relates to the whole 'elements of print' the elements are broken down to give further understanding. For example the page on uncoated paper will give you definitions for both uncoated and paper so you can put the 2 together to understand the term and then on the opposite page it'll have the design definition and more information on the subject. I feel this method is a great way of understanding subjects you don't necessarily know.

To differentiate between the two pages I've come up the idea of changing the orientation and font of one side just so it's obvious to the reader they're meant to be read individually and not together as a unity!!!

To differentiate between the two pages I've come up the idea of changing the orientation and font of one side just so it's obvious to the reader they're meant to be read individually and not together as a unity!!!

Design for print- peer feedback

In todays session we got together in small groups of around 8 to discuss our concepts, development and any issues or questions we needed help/advice with. This was all led by us so there was no interference from the tutors at all giving it a more informal tone to it and taking away any stress and nerves that come along with crits. It was also to teach us about structuring a crit because shortly we're going to have to organise our own crits as we develop more and the modules become more self directed.

Firstly I talked about my print information pack, I didn't a full on cemented concept so I basically talked about all my process research I had undertaken and the visits I had been on recently to aid in the whole process of creating a print manual. I then discussed my whole format concept which is to create a multi format publication where each different size represents a different category of print. They all work together but individually as well. I also discussed my issue with using photography within my info pack, I know it's necessary to have some form of imagery within my work but I find photos difficult to work with, plus I'm the worst photographer, I some how to make even the simplest of images look horrific.

My feedback was pretty standard and unhelpful 'It's nice' 'god idea' etc... But there were a few good points raised. The first was that instead of pictures maybe vector everything, this is something I did throughout the whole of last year and it's something I want to step away from. Plus I think it would be hard to represent some processes and show examples through vectors, well actually quite impossible to show examples. But then someone suggested just have a monotone overlay over each image meaning they won't need too much editing, plus personally I think colour overlays are beautiful and really on trend at the moment, they also work on a whole range of coloured stock as opposed to full colour photography.

The other point that was raised during this crit was that it all just seemed a bit too normal and boring which is what I have thought all along but been stuck on. But Sam suggested adding a theme to it and when we got chatting about the whole category idea, about how each book is a different format but how they all come together to represent one whole book. He said it was quite similar to science and elements, how they come together to form compounds. So my whole publication would be the 'compound' and each individual category book would be the 'element'. It could be called the 'elements of print' and have a science theme running throughout, this concept got me excited and I just wanted to go away at this stage and research. But the theme has definitely cemented my concept and given me something to focus on and progress with as opposed to half heartedly committing and dithering around with developing nothing.

Firstly I talked about my print information pack, I didn't a full on cemented concept so I basically talked about all my process research I had undertaken and the visits I had been on recently to aid in the whole process of creating a print manual. I then discussed my whole format concept which is to create a multi format publication where each different size represents a different category of print. They all work together but individually as well. I also discussed my issue with using photography within my info pack, I know it's necessary to have some form of imagery within my work but I find photos difficult to work with, plus I'm the worst photographer, I some how to make even the simplest of images look horrific.

My feedback was pretty standard and unhelpful 'It's nice' 'god idea' etc... But there were a few good points raised. The first was that instead of pictures maybe vector everything, this is something I did throughout the whole of last year and it's something I want to step away from. Plus I think it would be hard to represent some processes and show examples through vectors, well actually quite impossible to show examples. But then someone suggested just have a monotone overlay over each image meaning they won't need too much editing, plus personally I think colour overlays are beautiful and really on trend at the moment, they also work on a whole range of coloured stock as opposed to full colour photography.

The other point that was raised during this crit was that it all just seemed a bit too normal and boring which is what I have thought all along but been stuck on. But Sam suggested adding a theme to it and when we got chatting about the whole category idea, about how each book is a different format but how they all come together to represent one whole book. He said it was quite similar to science and elements, how they come together to form compounds. So my whole publication would be the 'compound' and each individual category book would be the 'element'. It could be called the 'elements of print' and have a science theme running throughout, this concept got me excited and I just wanted to go away at this stage and research. But the theme has definitely cemented my concept and given me something to focus on and progress with as opposed to half heartedly committing and dithering around with developing nothing.

Design for print- progress crit

Today we had a critique with Phil following on from last weeks peer feedback, this was slightly more structured and a tad more formal than last week. As much as last week helped we did digress quite a lot so having Phil helped keep things on topic more and he also raised more questions for us to think about.

We had a choice of proposing either our print or web concept and development, I decided on the print brief because it's something concept wise I was unsure about since the feedback session last week. I proposed my new and improved print manual with a theme which I have decided to stick with to develop and strengthen it. I informed the group and Phil of my 'Elements of print' concept and how all the books come together to form a larger pack but work on their own and their different formats etc...

I mainly received all of my feedback off Phil and was all nearly focused on how I was going to interlink my tone of voice with both the concept of science, the technical language used and the target audience of people with a basic existing knowledge of print but who would like to use the manual as a reference, on going development through the info pack. He suggested using technical language to fit in with the theme but then I don't particularly want to completely lose people through terminology, but then again it could be the opposite end of the scale and patronise them. It was suggested to me that I should use quite a technical terminology but break it down so that it's understandable and easy to follow.

I've never really considered this point when developing this concept and actually thinking about it now it is actually a key component in the final info pack. It's completely pointless creating something themed around the sciences and print without using words used in both industries, if I created the info pack with only bearing my audience in my tone of voice it could turn out very bad because it would just appear stupid; that there is this chemistry themed print book but the text inside is completely different to the design... I really need to go away and have a longer think about what it is that I'm going to do, selecting a theme takes full commitment in all areas, not just the design. I need to think of something creative that will break down and explain words other than a glossary. Lorraine gave me the idea of breaking down words into their separate individual meanings (elements) and how two seperate things can come together to form a word (compound) such as thermo-chromatic which broken down means; heat and colour.

I then went away with Sam and had a quick discussion about the whole concept of words coming together and breaking them down in a science themed way. I looked at the way how compounds are drawn and how I can illustrate a compound with the different elements which would be the separate words with a small definition. I came up with this which I quickly drew up, each title page would have this illustration as a way of breaking down and briefly explaining the subject in a manner in which the audience will understand.

We had a choice of proposing either our print or web concept and development, I decided on the print brief because it's something concept wise I was unsure about since the feedback session last week. I proposed my new and improved print manual with a theme which I have decided to stick with to develop and strengthen it. I informed the group and Phil of my 'Elements of print' concept and how all the books come together to form a larger pack but work on their own and their different formats etc...

I mainly received all of my feedback off Phil and was all nearly focused on how I was going to interlink my tone of voice with both the concept of science, the technical language used and the target audience of people with a basic existing knowledge of print but who would like to use the manual as a reference, on going development through the info pack. He suggested using technical language to fit in with the theme but then I don't particularly want to completely lose people through terminology, but then again it could be the opposite end of the scale and patronise them. It was suggested to me that I should use quite a technical terminology but break it down so that it's understandable and easy to follow.

I've never really considered this point when developing this concept and actually thinking about it now it is actually a key component in the final info pack. It's completely pointless creating something themed around the sciences and print without using words used in both industries, if I created the info pack with only bearing my audience in my tone of voice it could turn out very bad because it would just appear stupid; that there is this chemistry themed print book but the text inside is completely different to the design... I really need to go away and have a longer think about what it is that I'm going to do, selecting a theme takes full commitment in all areas, not just the design. I need to think of something creative that will break down and explain words other than a glossary. Lorraine gave me the idea of breaking down words into their separate individual meanings (elements) and how two seperate things can come together to form a word (compound) such as thermo-chromatic which broken down means; heat and colour.

I then went away with Sam and had a quick discussion about the whole concept of words coming together and breaking them down in a science themed way. I looked at the way how compounds are drawn and how I can illustrate a compound with the different elements which would be the separate words with a small definition. I came up with this which I quickly drew up, each title page would have this illustration as a way of breaking down and briefly explaining the subject in a manner in which the audience will understand.

- In OUGD504

Concept workshop

This afternoon Phil briefed us on a concept task which will also help us with our design production print brief. We were asked to choose 3 words from a jar and then 1 from the second jar. By then eliminating two of the three we would be left with the two words to use to create our concept.

We had the following:

(Jar 1)

Abacus

Pipe

Ball

(Jar 2)

Hotel

So with these options we then decided to draw a mind map and think of as many words as possible which relate to each object. We were able to explore each word just as much as each other, however abacus seemed like possibly the more intriguing word to use for our main concept.

Once we had come up with our words to use, we then applied them to possible concept ideas. We had so many different ideas, considering audience especially and whether the concept should be focusing on a younger audience or adults, seeing as we are designing a hotel.

Our initial ideas consisted of:

- Having slides for children and adults to move around the hotel

- Having a hotel for blind people and making it a sensory experience with brail

- Making it really chic and trendy in the centre of the city

- We considered the fact that the plural of Abacus is Abaci - suggested name?

- The idea of incorporating geometric design within the hotel to represent the balls

- Perhaps sectioning off the hotel to incorporate the history of Abacus - countries?

Therefore it is clear that initially we were quite concerned about making a strong and obvious link to the Abacus itself. Looking at the history and reflecting it's existence within the hotel.

However, the more we thought about it and discussed our ideas, the more it became apparent that it would possibly be a more successful concept if we were to essential go 'back to basics' making a link to the abacus itself which was designed for children to use in the beginning. This subtle link allows us to concentrate on making our concept more of a simplistic design, driven by more simple ideas as opposed to complicated it and making it too complex.

The concept was to create a treehouse type hotel where each room was a pod on its own tree (the ball on the abacus) and to move between them and the main recreational room was through rope bridges (the stick on the abacus). It's like an abacus blown up on a larger scale and suspended amongst trees.

It was Jamie, Jake, I whose task it was to come up with a logo, we each designed our own interpretation of the concept and then democratically decided which was more suited to the concept. I started doodling onto paper a few sketches but didn't really get any where with them so I decided to take these mere doodles and digitalise them to grasp a better idea of what they would really look like.

Firstly is the simple geometric interpretation of a circular pod suspended in the tree, it's not obvious what it is but once you know the concept it's easy to deconstruct and figure what is what. The font is quite a tall font in stature, there fore I chose it to represent the trees you're suspended in and the surrounding forestry.

The one below looks like it's simply been underlined but in fact the meaning behind it is that it represents a sub section of an abacus and also our hotels being suspended.

And then this was a digital mock up of Jakes idea of having the ball suspended in a tree like shape.

Final presentation boards

Subscribe to:

Comments (Atom)

Labels

- Collaborative (14)

- Creative suite workshop (3)

- Design Practice 2 (26)

- Design for print (19)

- Design for print and web (13)

- Design for web (19)

- OUGD503 (36)

- OUGD504 (56)

- OUGD505 (26)

- Responsive (36)

- Web session (4)

Archive

Powered by Blogger.

Copyright 2010. All rights reserved.

RSS Feed. This blog is proudly powered by Blogger and uses Modern Clix, a theme by Rodrigo Galindez. Modern Clix blogger template by Introblogger.